If you're inspired to recreate this project, cutting velvet for a directional look can be tricky. At WANXIE, we specialize on shark solutions for manufacturers to saving material in high quality. Knowing what you’re doing and having the right tools, it is entirely possible to cut directional velvet fabric with a minimum of waste. This does not only help you save money, but also helps the environment by using less fabric. Below are some thoughts that may inspire you to get creative with your velvet cutting.

Vertical Velvet Cutting for Wholesale Production: How To Get The Most From This Laying Technique?

First, though, you need to know the fabric. Directional velvet has a nap, the fibers going in one direction. It’s important to remember this so as not to make mistakes when cutting. Always place the velvet material fabric with the nap running in the same direction on both pieces. This is to make the finished product have a more consistent appearance. You might also use puzzle like pattern pieces that fit together, leaving you less leftover fabric. This is useful for larger orders, where every inch of material used counts.

How to select the suitable cutting tools for directional velvet efficiently?

As important as the cutting process is, so too are choosing the right tools. For the nap of velvet, your best bet is sharp scissors or a rotary cutter. Sharper blades result in cleaner cuts and help avoid the fabric fraying. If you're going to use scissors, have longer-bladed ones. It’ll make more streamlining cuts through bigger stuff. A rotary cutter does a great job, especially if you have a cutting mat. Always ensure your tools are clean and in good working order. Dull blades can ruin the cutting process but also result in jagged edges and more waste.

And finally, always double check your cutting area. Ensure it’s clean and with plenty of light. If your work surface is a mess, you’ll make mistakes, and waste fabric. Having everything sorted, you’ll have better ways to cut directional velvet cloth fabric. With the right methods and tools, welcome to wanxie help you reduce waste and save time on cutting.

How Can You Minimize Waste Sewing with Pile or Nap Velvet?

When dealing with directional velvet we want to be smart about our cutting. Directional velvet is a kind of fabric that looks friendly on one side, with a soft, fuzzy feel. But if we’re not cutting it with care, we can end up wasting a lot. One neat trick for minimizing waste is planning the cuts ahead of time. We can map how to use it before making cuts. That brings us to where we can cut that without having any extra waste. Another good idea if you have one is to use a garment cutter, which are these neat things that people clip the ends of ribbons and fabrics on so let gravity help you. This implement can ensure cleaner cuts and lower the likelihood of fraying, which will also save you from wasting fabric.

Where to Get a Quality Directional Velvet for Max Efficiency?

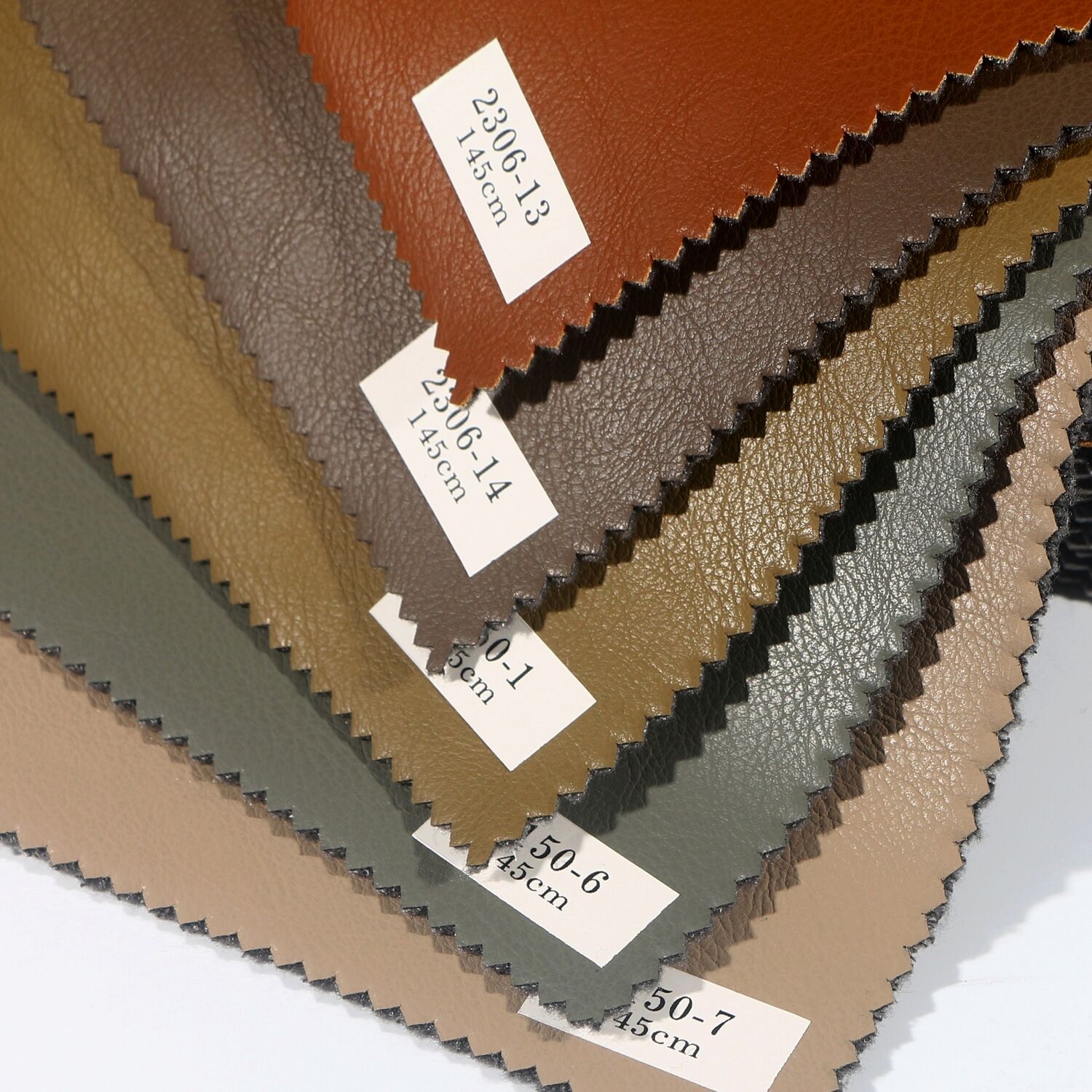

It’s the high-quality directional velvet source that is so critical in minimizing waste. When we purchase good velvet, it does not merely appear to advantage; it actually cuts better. A way to source this velvet is through reputable vendors. At WANXIE, we establish good relationship with the fabric suppliers to make sure an optimum quality of the products. It is easier to cut high end velvet, and often has fewer imperfections. This, in turn, means there’s less of a likelihood that they’ll waste fabric thanks to defects. You may be able to find local suppliers as well.

How to Apply Green Concepts in Wholesale Directional Velvet Cutting?

When it comes to cutting directional velvet more sustainability, we need good habits that are good for the environment. First, we need to train our team in how to cut fabric efficiently. At WANXIE, we can conduct workshops to help everyone learn the best cutting. Also, it is not only that we can save resources with it but also the quality of our products will increase. Next we need a program to recycle unused fabric. Smaller items may be salvaged and used in other projects, or donated to schools and local artists. In other words, we are helping our community and working efficiently with our materials.

Table of Contents

- Vertical Velvet Cutting for Wholesale Production: How To Get The Most From This Laying Technique?

- How to select the suitable cutting tools for directional velvet efficiently?

- How Can You Minimize Waste Sewing with Pile or Nap Velvet?

- Where to Get a Quality Directional Velvet for Max Efficiency?

- How to Apply Green Concepts in Wholesale Directional Velvet Cutting?